Explore Other Products

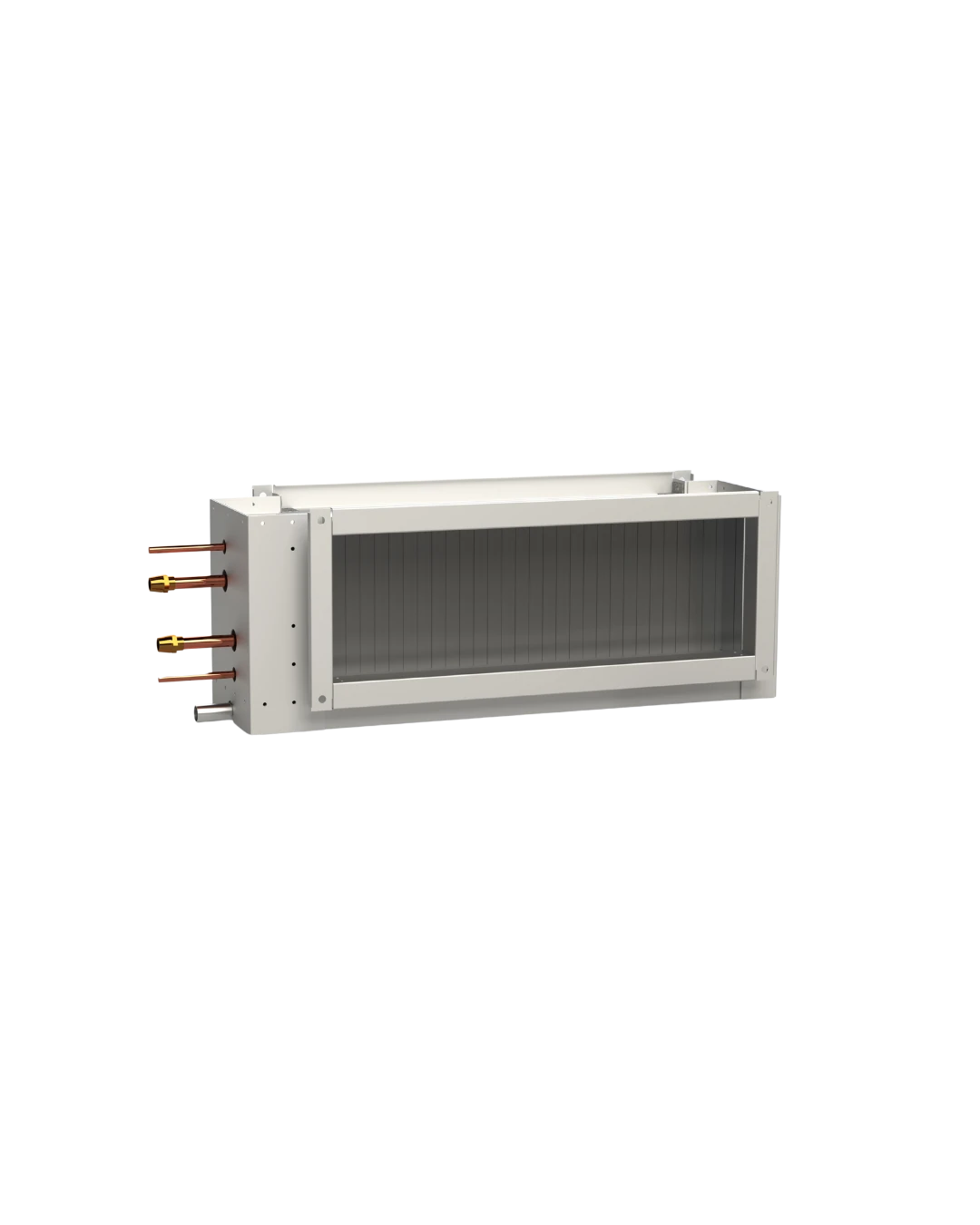

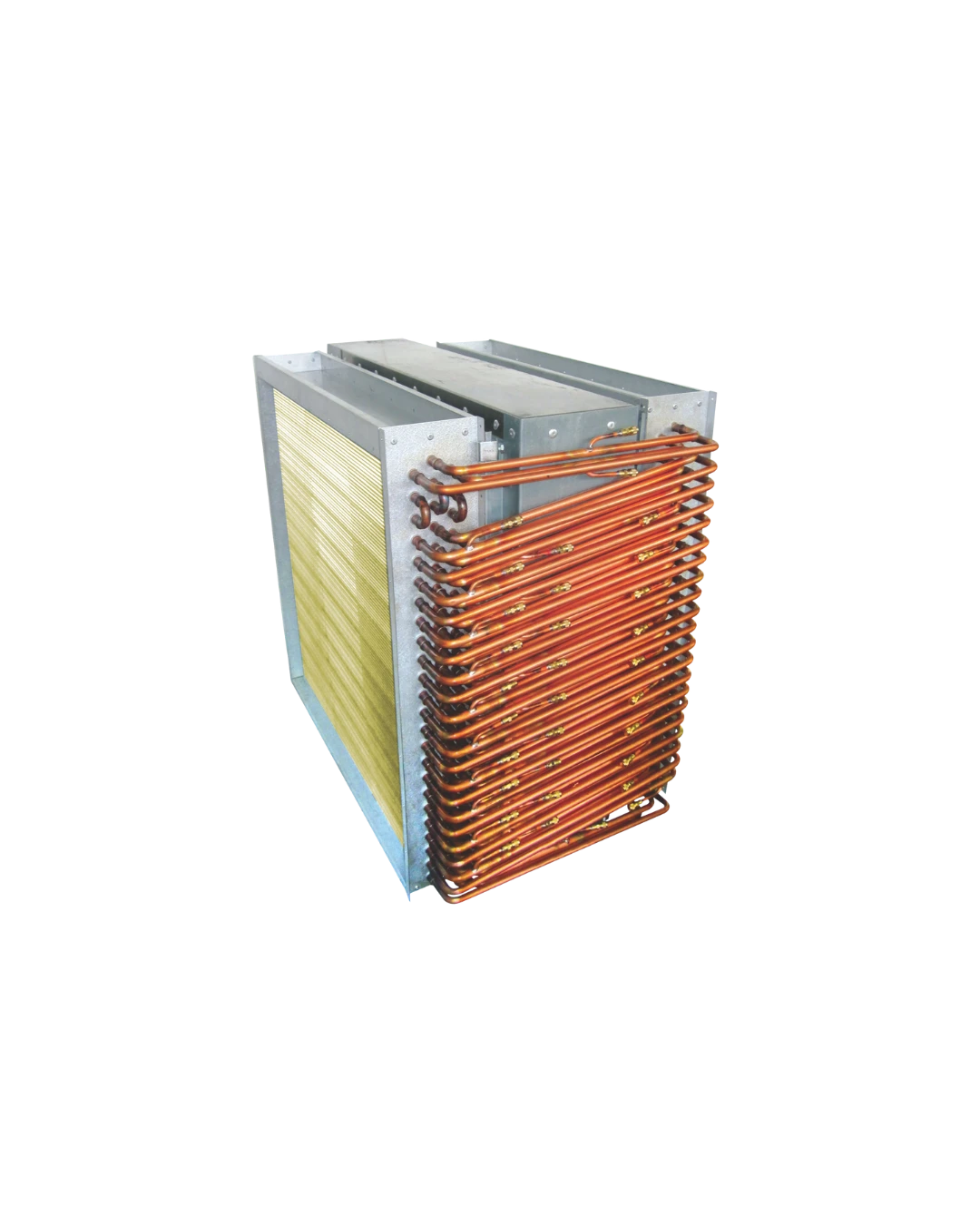

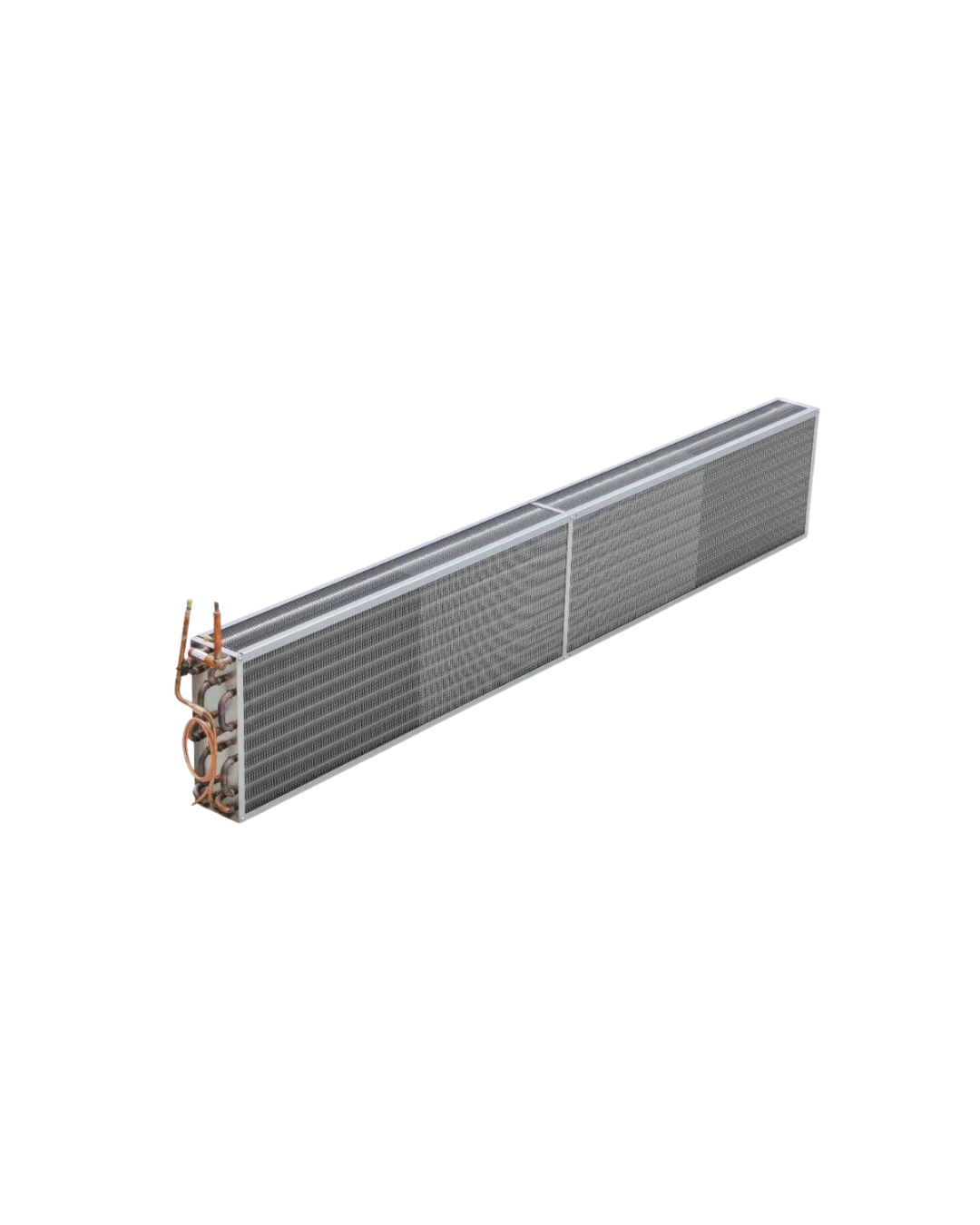

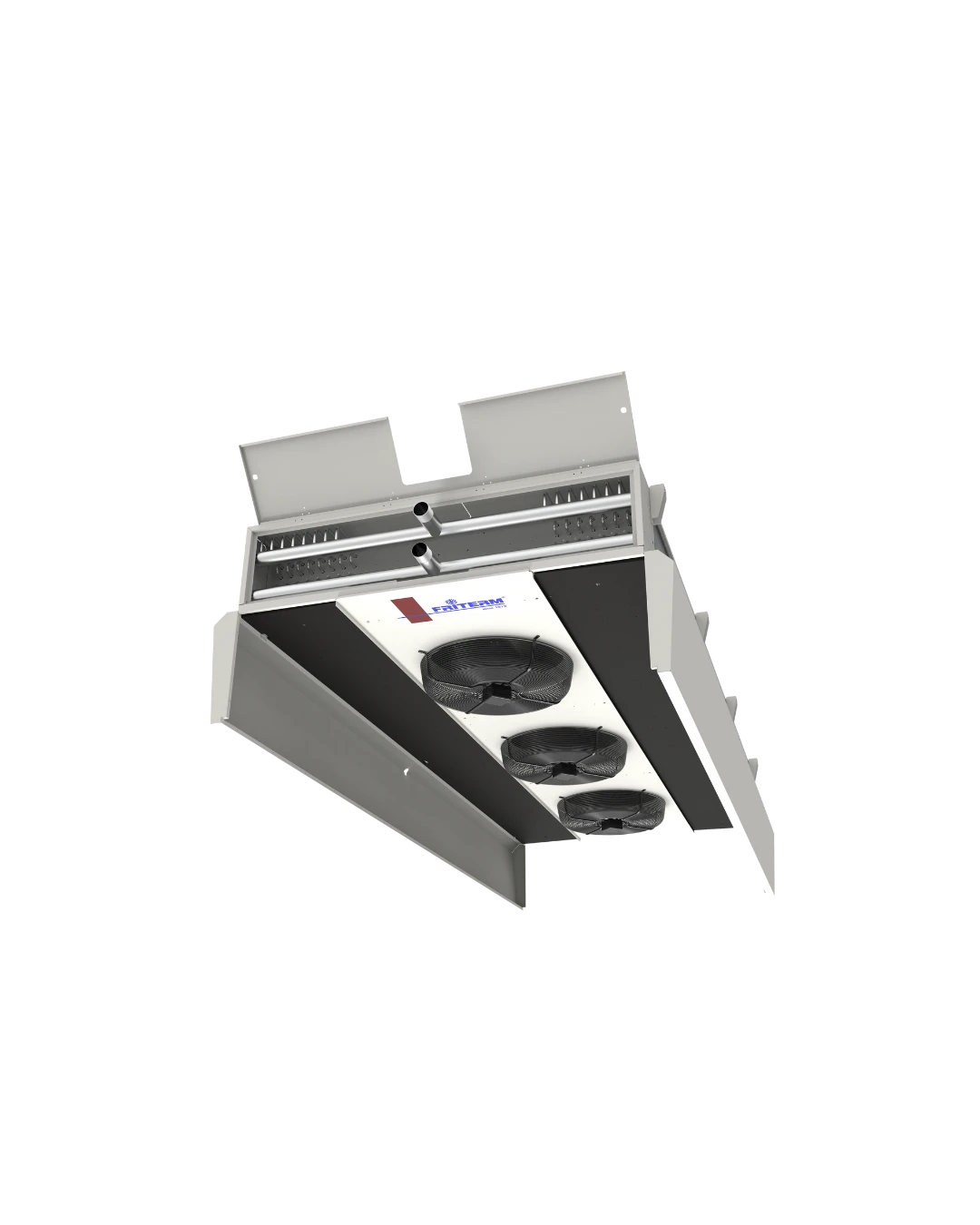

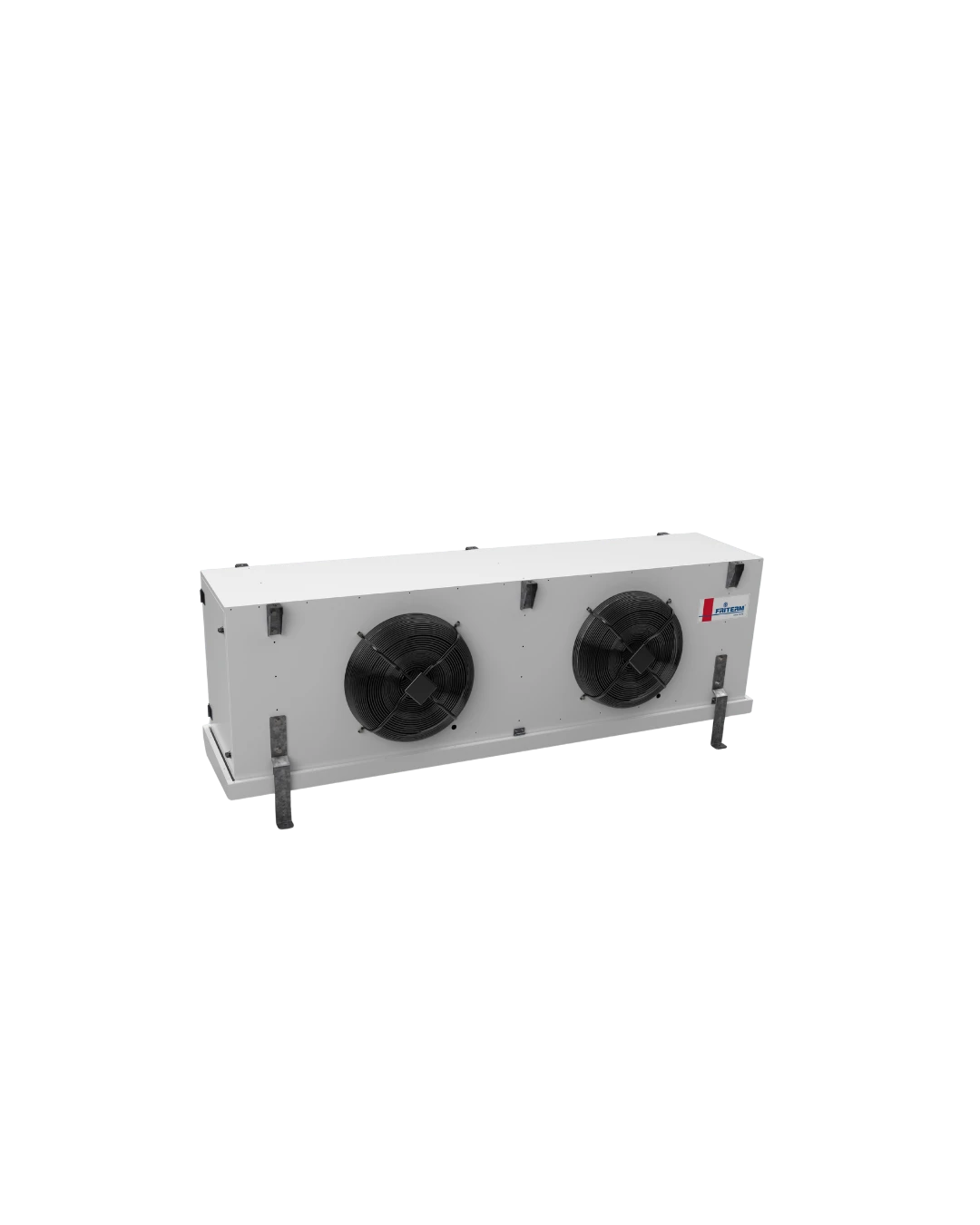

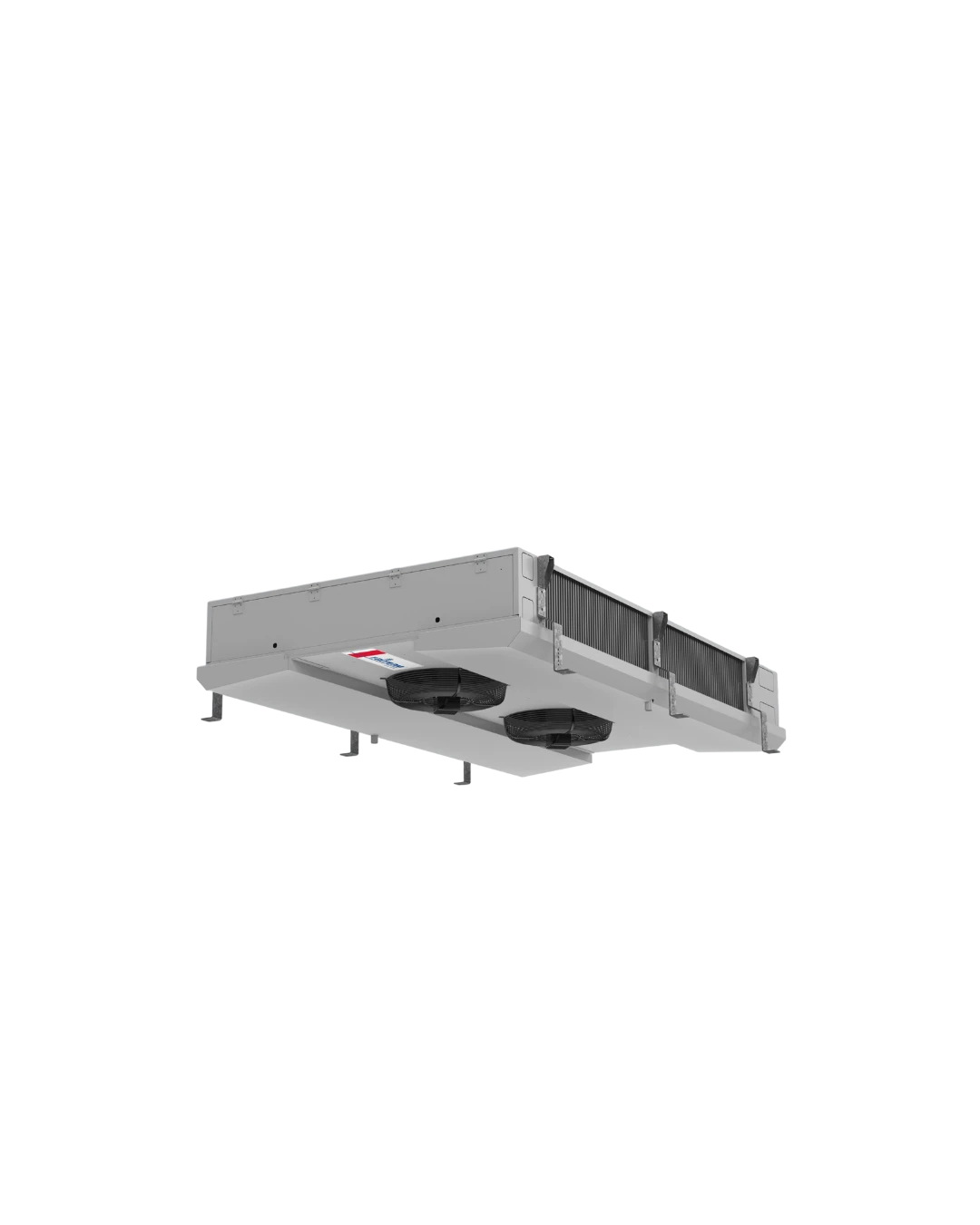

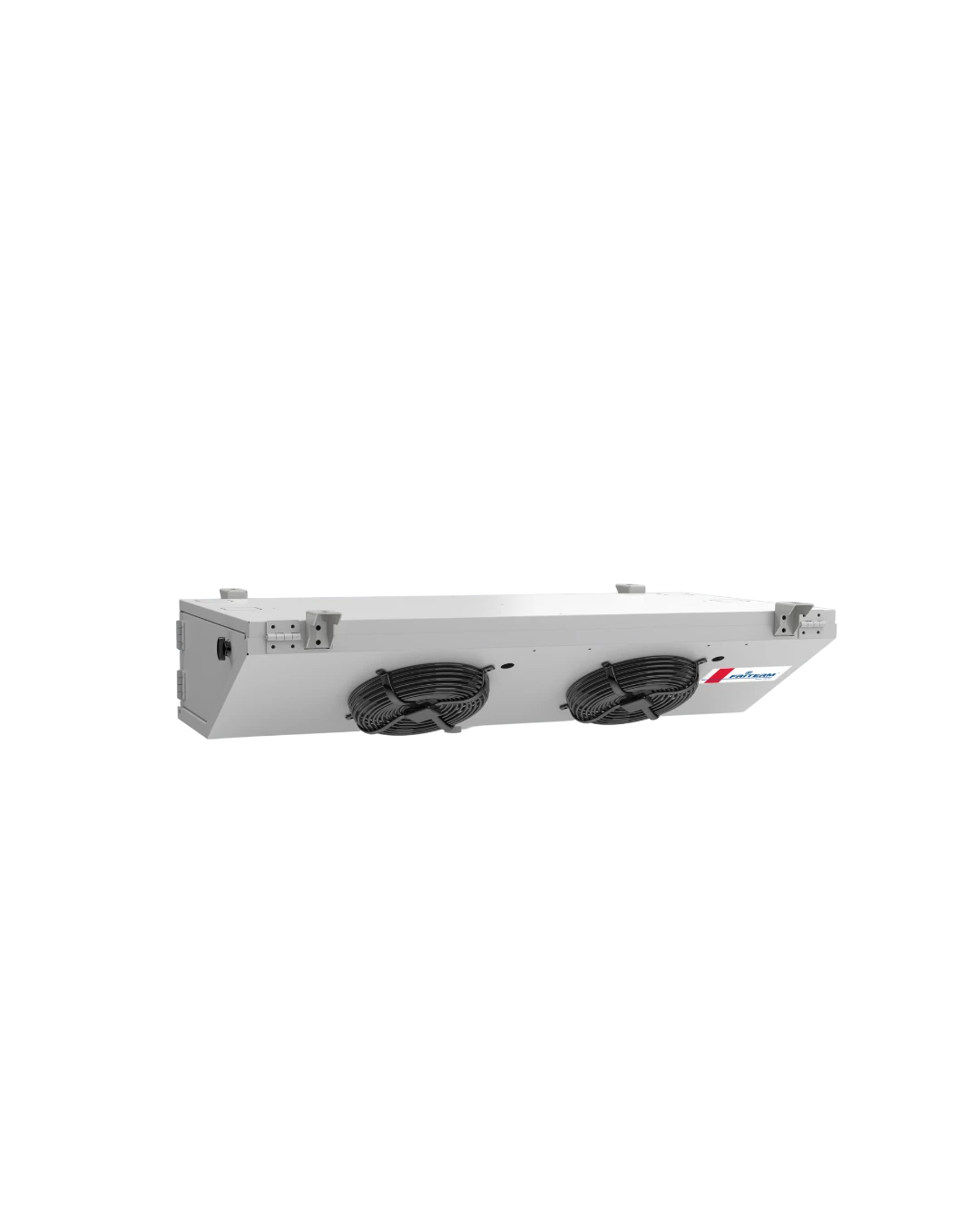

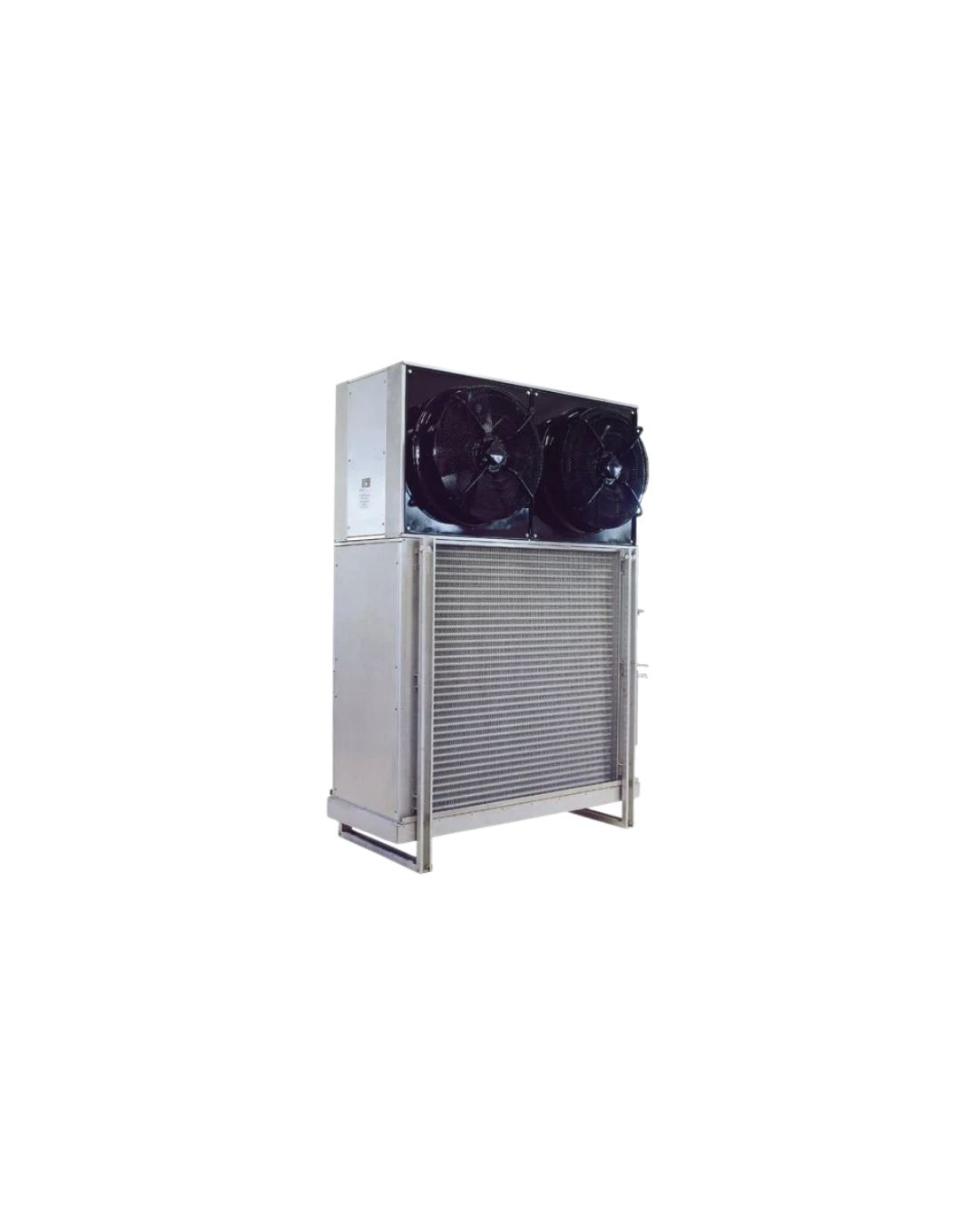

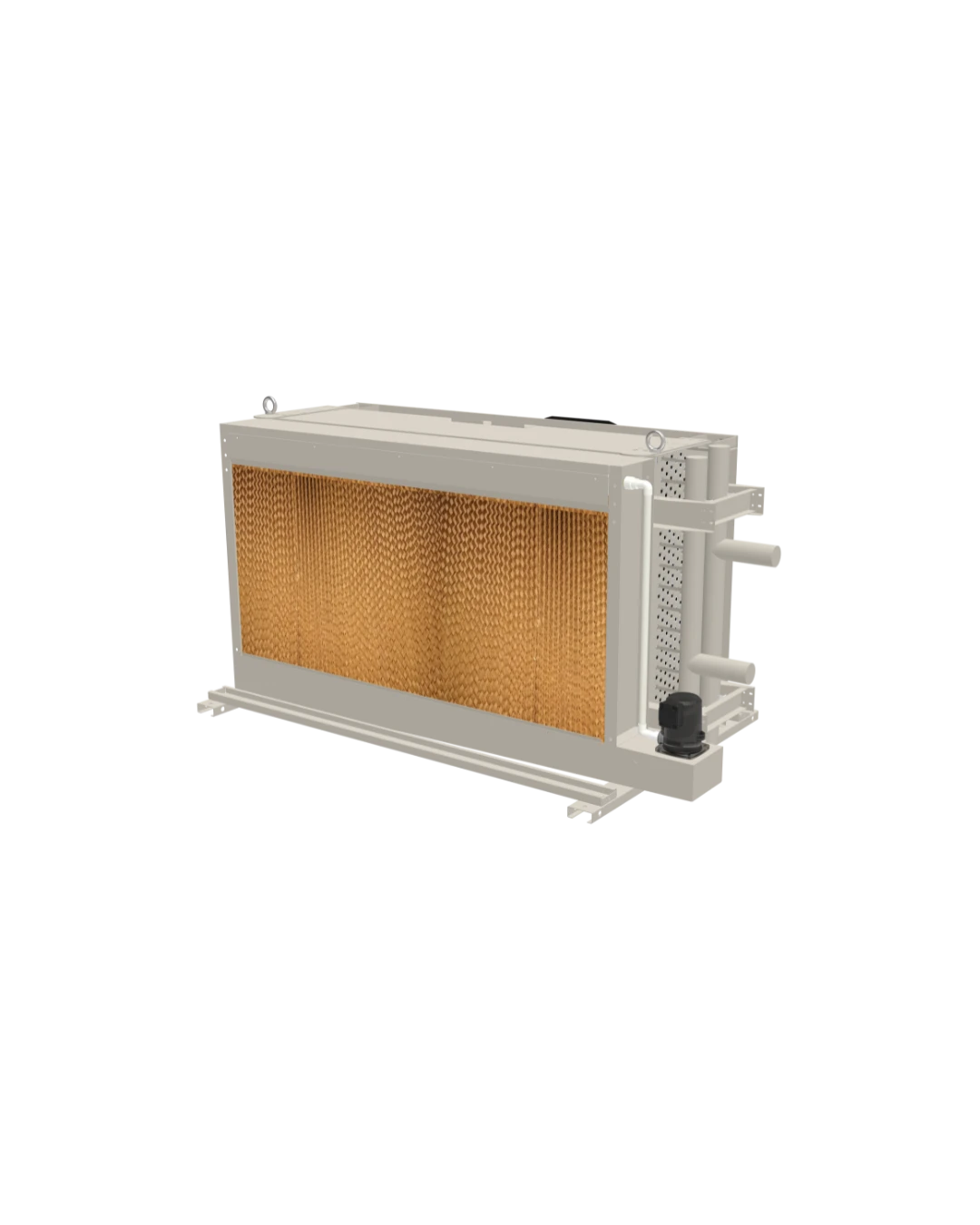

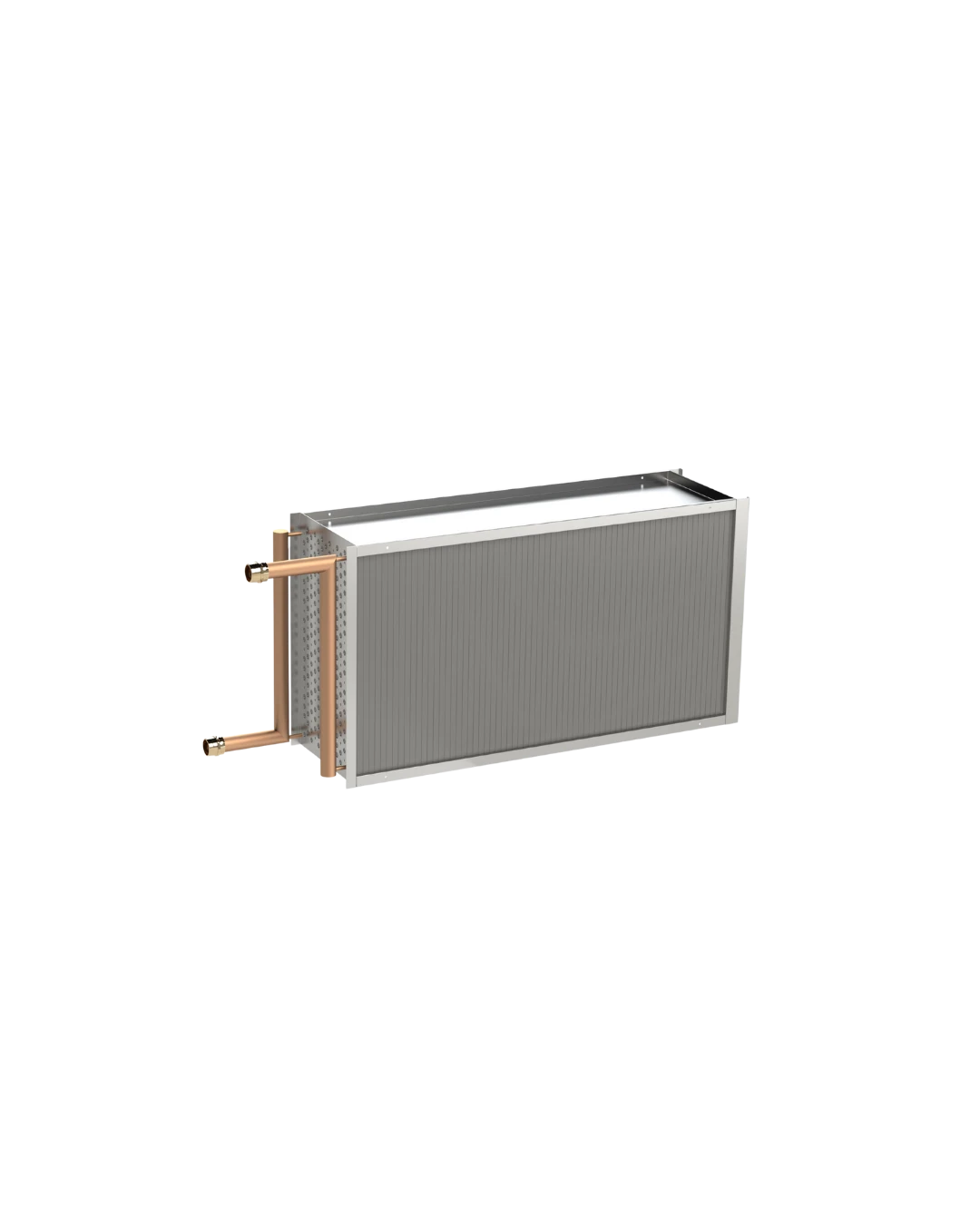

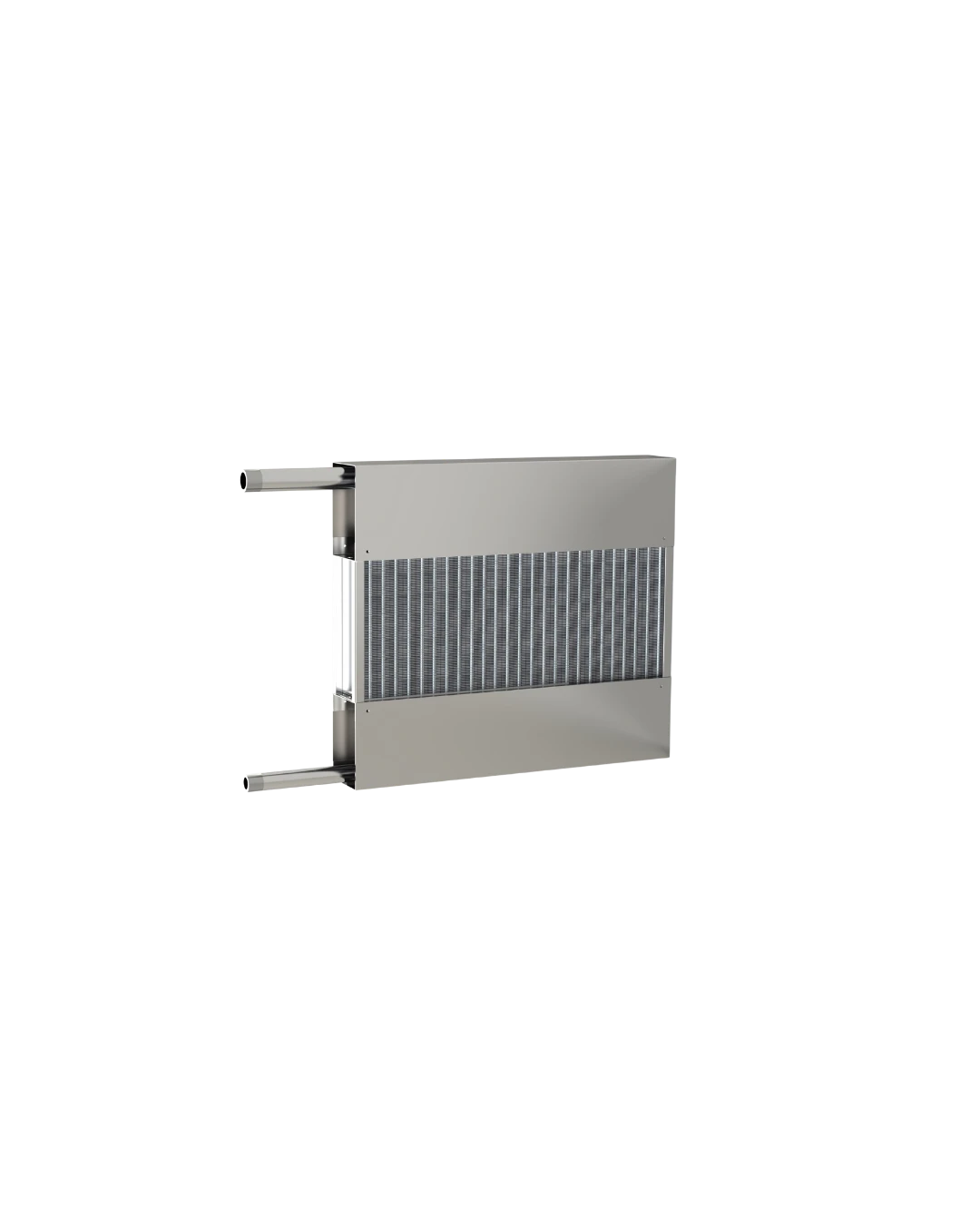

- Heat pipes can be produced in different types to meet various requirements. In cases where only heat recovery is essential, single and double coil vertical and angled horizontal heat pipe heat recovery coils are used. If the evaporation and condensation parts of the system need to be far apart, the system should have double coils. In such cases, a pump is used to ensure fluid movement between the coils. These systems are also called pumped heat pipe systems.

- Efficiency ranges from 50% to 70%. No power is required to operate the system.

- No maintenance is required.

- Galvanized or steel casing options are available.

- Aluminium, epoxy-coated aluminium and copper fins can be used.

- Straight and grooved copper tube types are available.

- The system is suitable for use with R134A, R404A and CO₂ fluids.

- There are separate Schrader valves for each circuit.

- The maximum working pressure is 28 bar.

- It can be tested at 34 bar.

- Production of vertical, angled and horizontal types is possible.

- The latent heat transferred is 1000 times greater than the heat that can pass through a copper plate or cable.

- Condensation and evaporation of the fluid occur at the same temperatures, ensuring high heat transfer even at low temperature differences.

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)