Your economic and reliable solution partner for all your needs.

Industrial refrigeration encompasses cooling systems that control heat and maintain the desired temperature and humidity levels in large-scale production facilities, storage areas, and processes. These systems have larger capacities, more durable components, and often more complex designs than commercial refrigeration systems.

They are widely used for preserving food, pharmaceuticals, chemicals and health products (e.g. serum and stem cells). The temperature range is -80°C to +25°C, but systems with storage temperatures between -5°C and +5°C are more common. Cold chain processes also depend on storage periods.

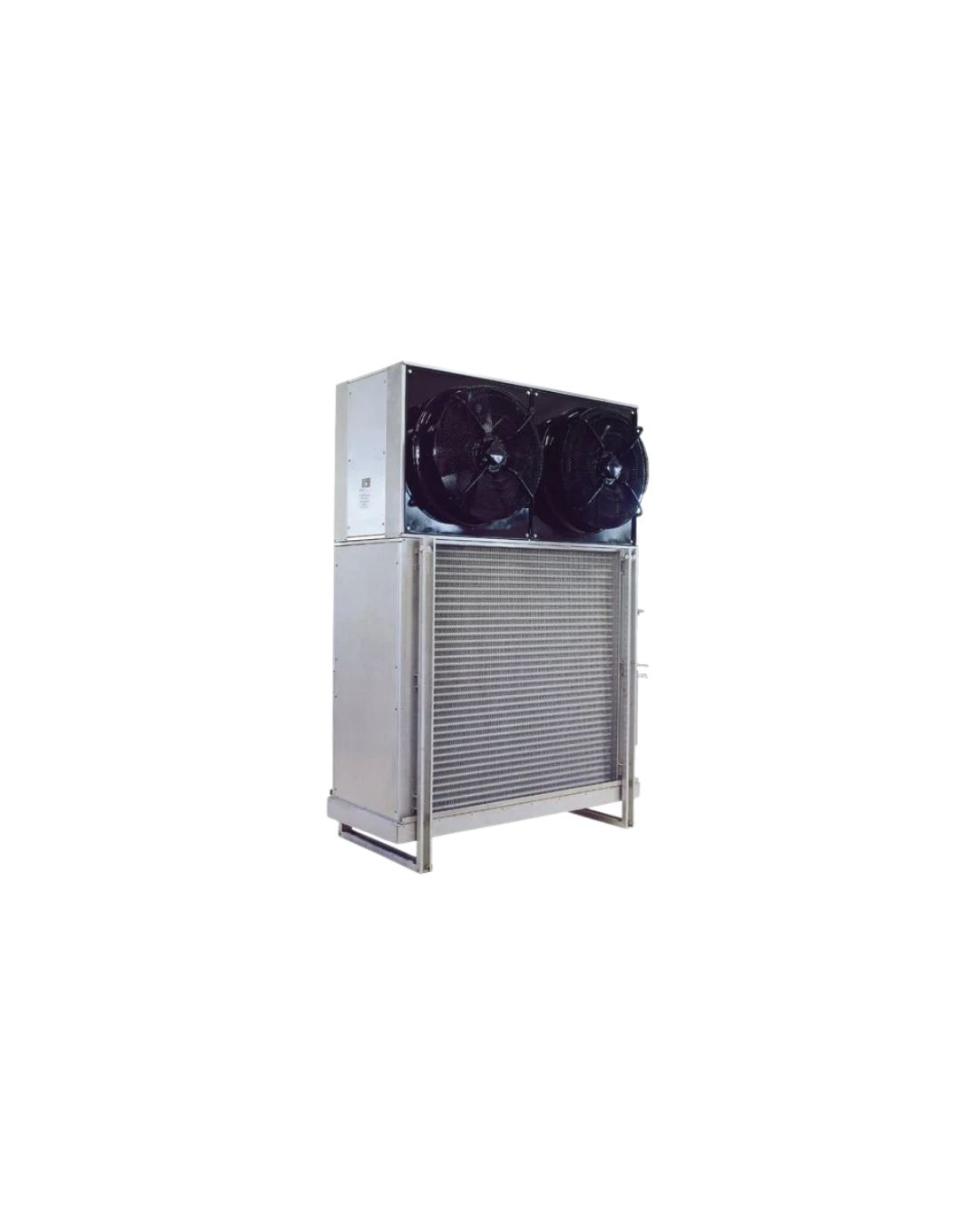

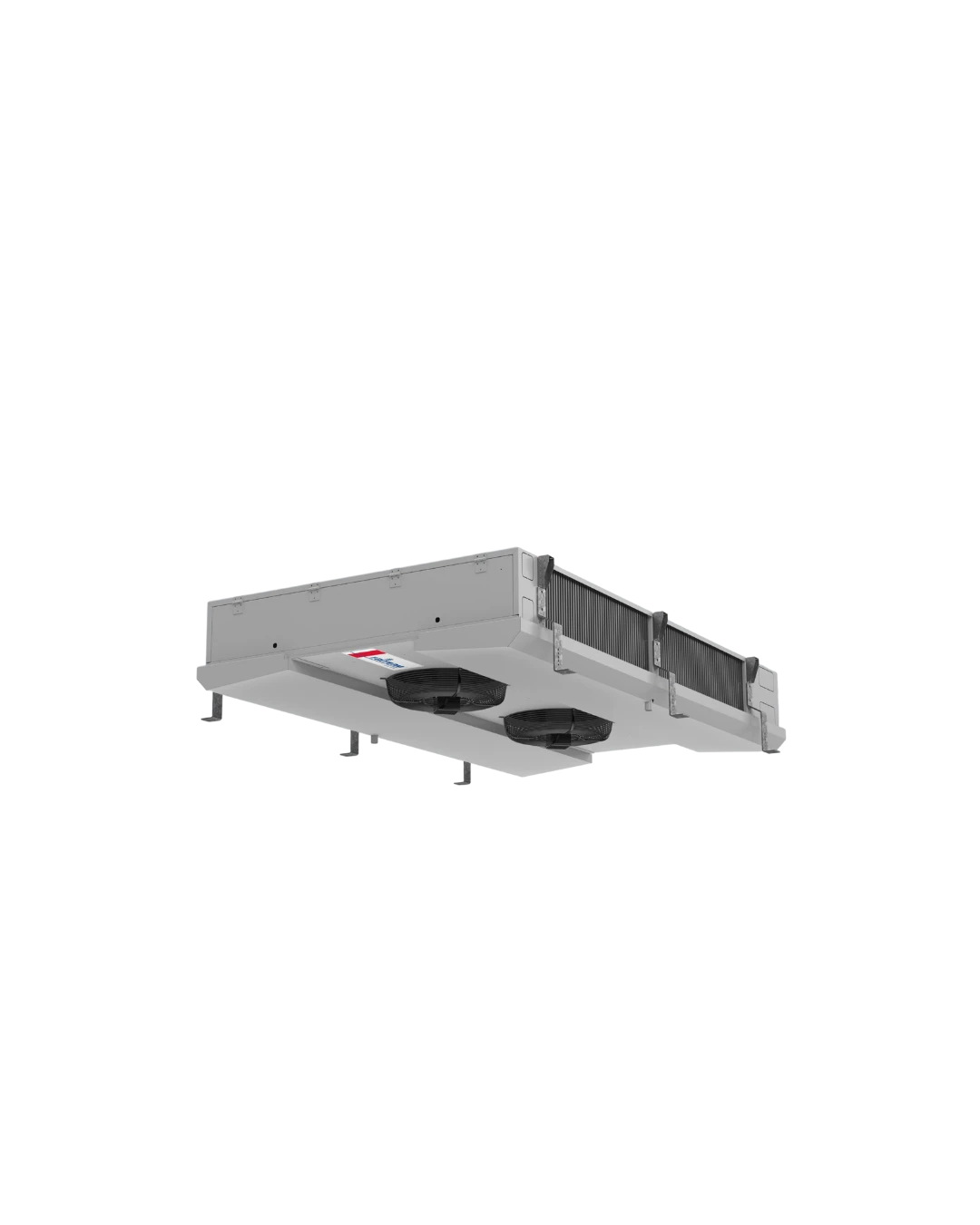

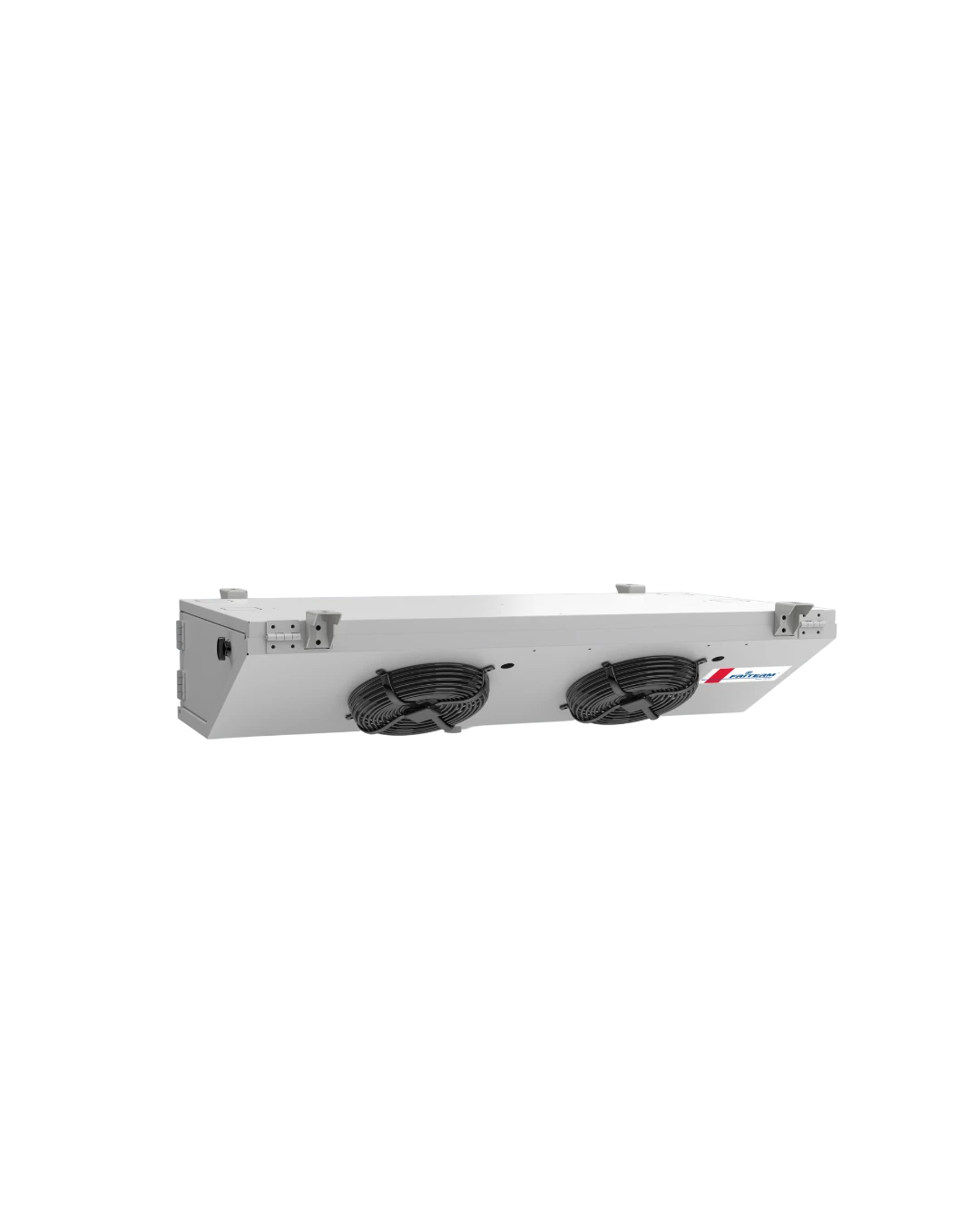

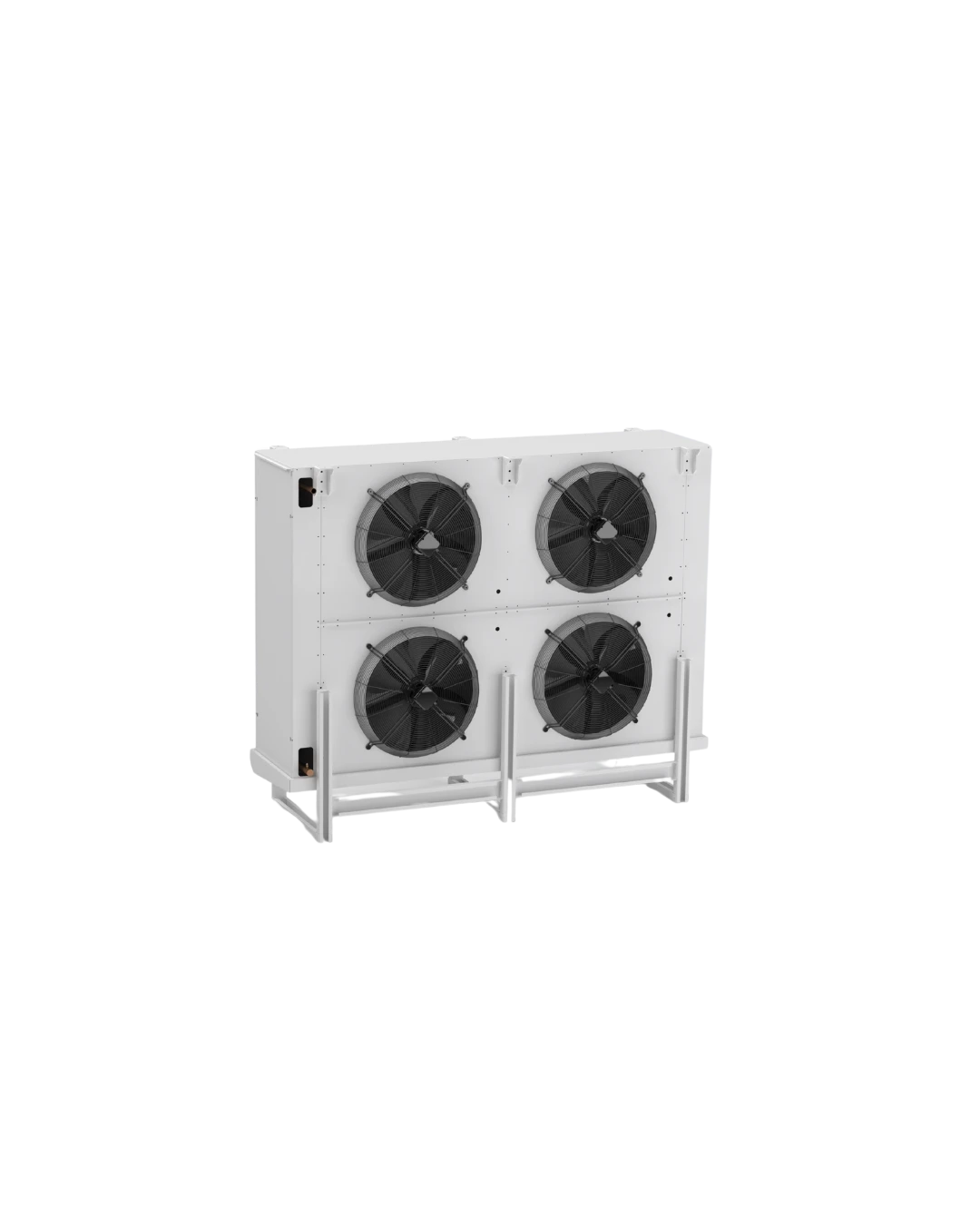

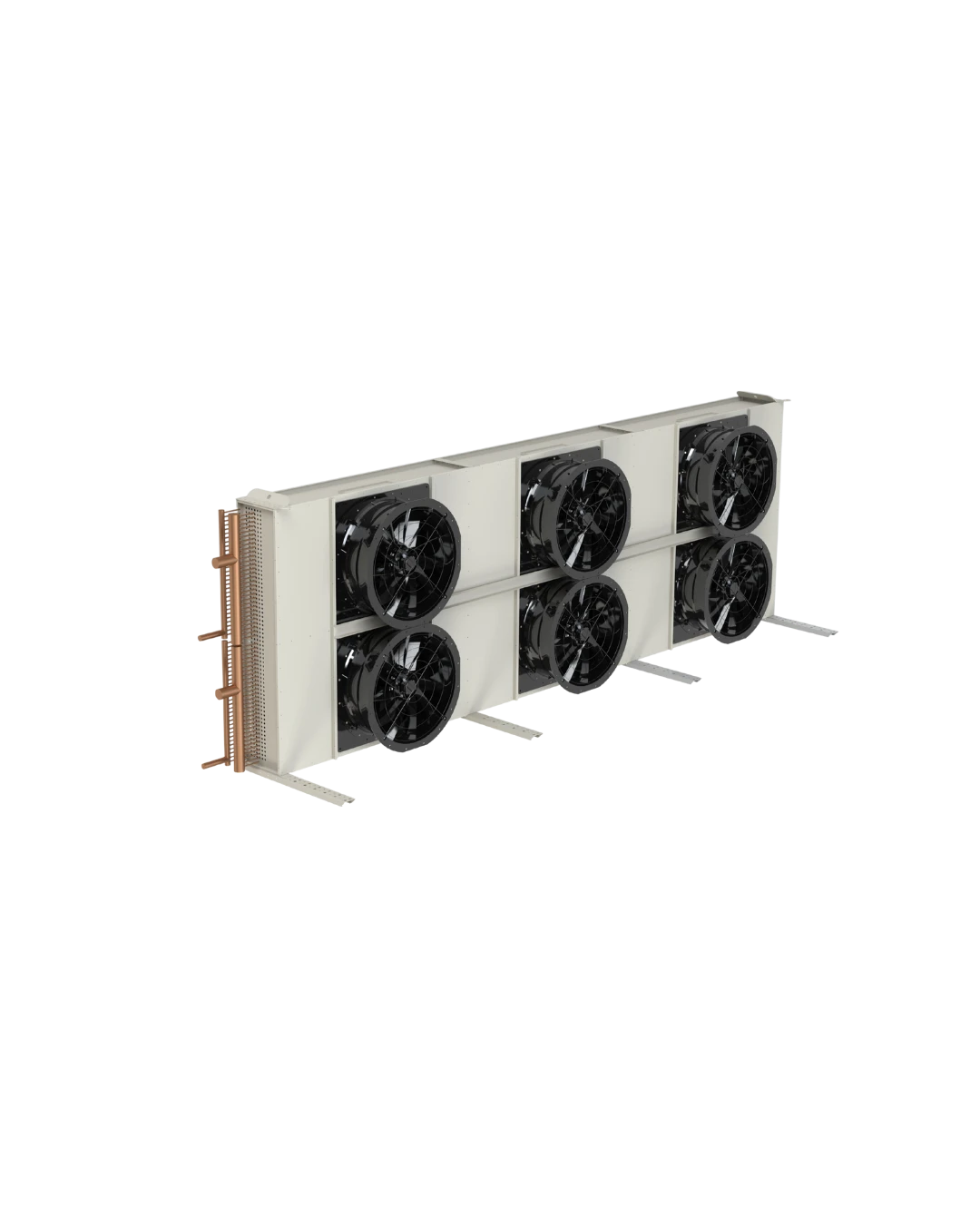

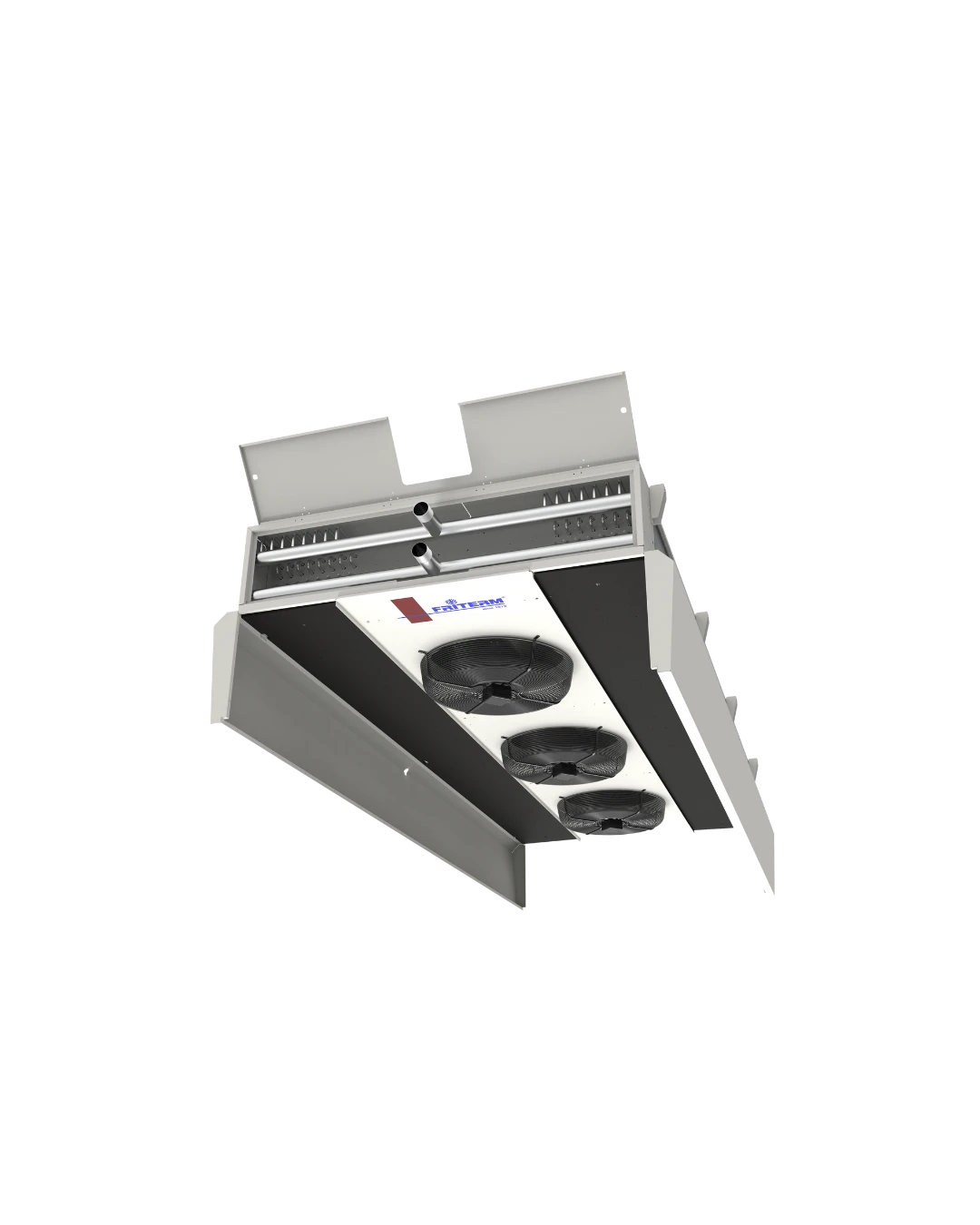

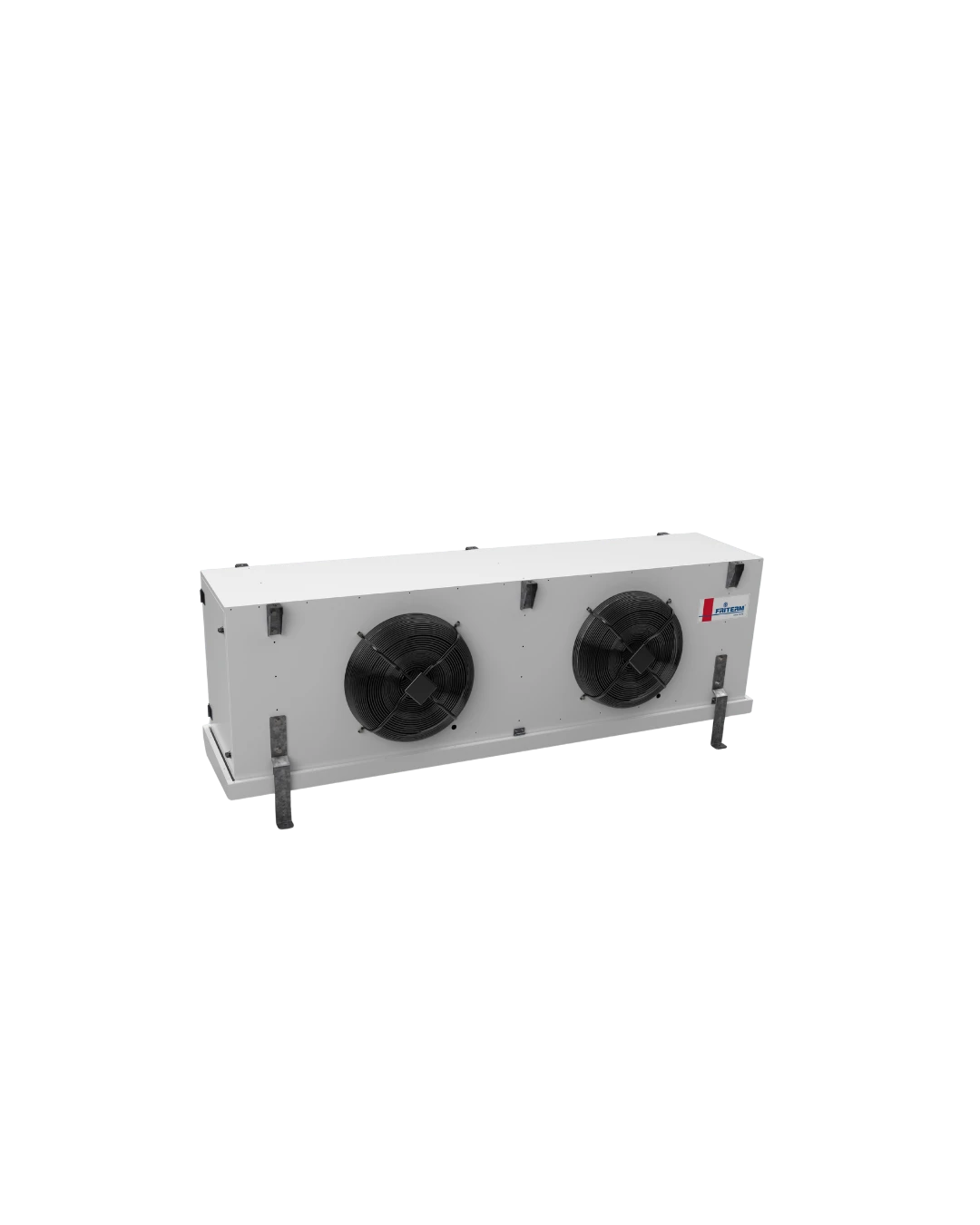

The choice of equipment for the refrigeration system depends on the type of refrigerant used. Friterm designs, manufactures and offers the FES/FEDD/FEWR series of evaporators (cold room evaporators) and the FCV/FCH/FCW series of condensers (air-cooled condensers) for refrigeration systems with fluorinated refrigerants (R404A, R407C, R134A, R410A, etc.) to the service of the sector. Designs can be made using our standard products, as well as for special projects (e.g. special shock cooling applications, fast cooling applications, large volume applications and marine/boat applications). Copper tubes and aluminum fins are commonly used in products with fluorinated refrigerants, while stainless steel tubes (for dairy plants) and aluminium tubes (for transport vehicles), as well as copper fins, are selected according to demand.

The NES series of evaporators (cold room evaporators) and the NCV/NCH/NCW series of condensers (air-cooled condensers) are designed by Friterm for use with ammonia (NH₃/R717) refrigeration systems. In ammonia products, the pipes are made of stainless steel, and the fins (lamellas) are made of aluminium.

The CES series of evaporators (cold room evaporators) and the CCV/CCH/CCW series of gas coolers (air-cooled) for carbon dioxide (CO₂/R744) fluid cooling systems are also designed and manufactured by Friterm. In carbon dioxide products, the tubes are made of copper and stainless steel, while the fins are made of aluminium and copper.

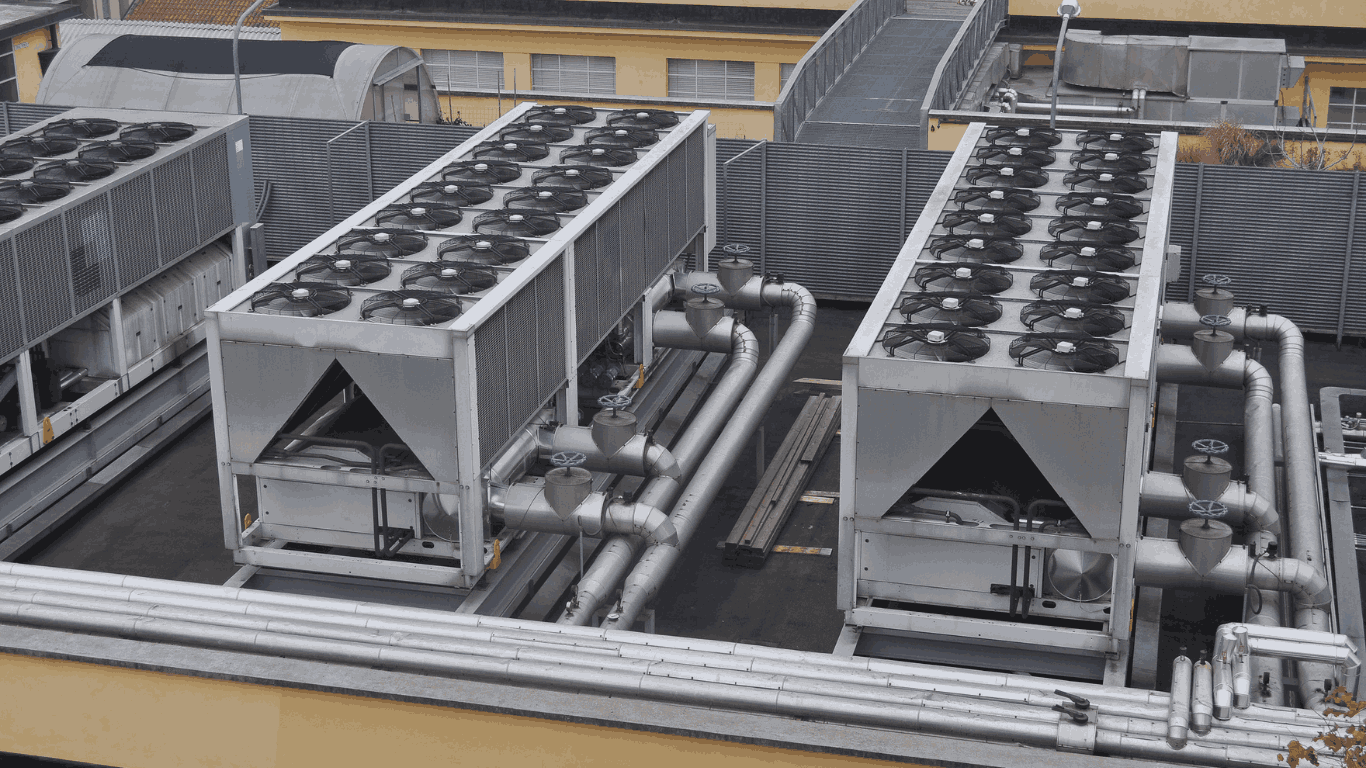

Friterm designs, manufactures and offers the GCS/GCDD/GCWR series of chillers for water/glycol fluid cooling systems to the industry. Designs can be created using our standard products, as well as designs specific to special projects. Water/glycol fluid products use stainless steel and copper tubes and aluminium fins. The use of stainless tubular products is becoming widespread, especially against the corrosive effect of glycol.

Inspired by nature, we produce products that touch every aspect of life.

Pre-Cooling

Low Temperature Storage

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)