We are a company that is committed to ethical principles and progressing towards becoming an environmentally-friendly industry, based on customer satisfaction in the production of finned tube heat exchangers since 1979.

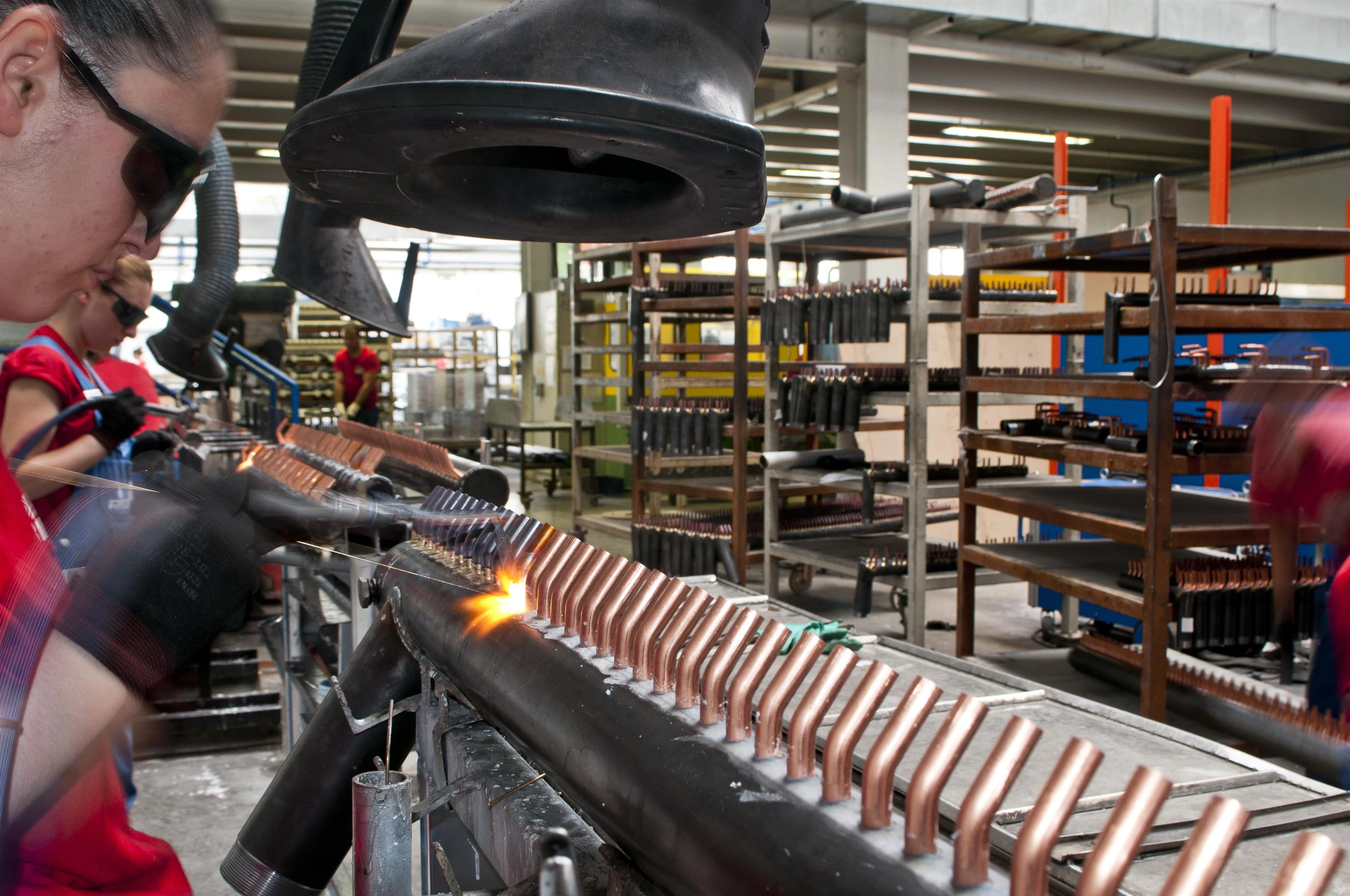

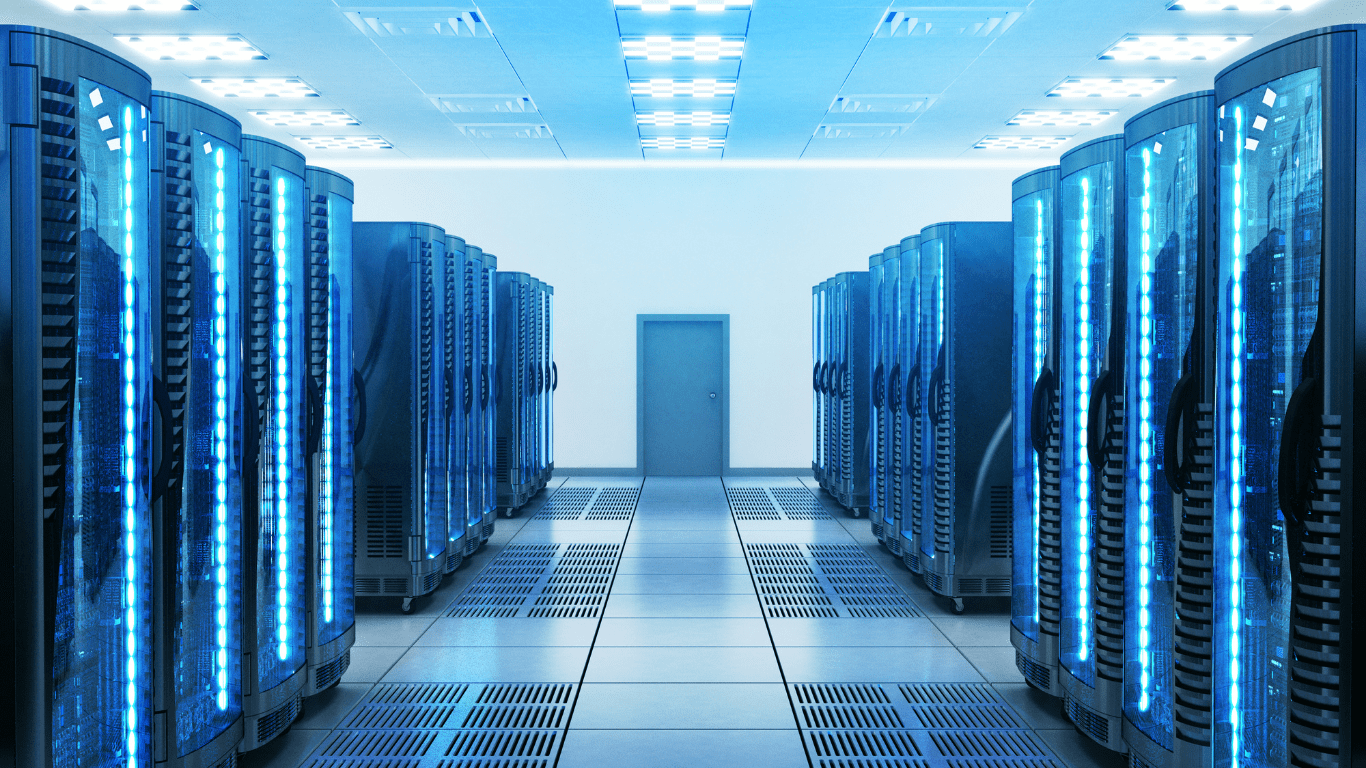

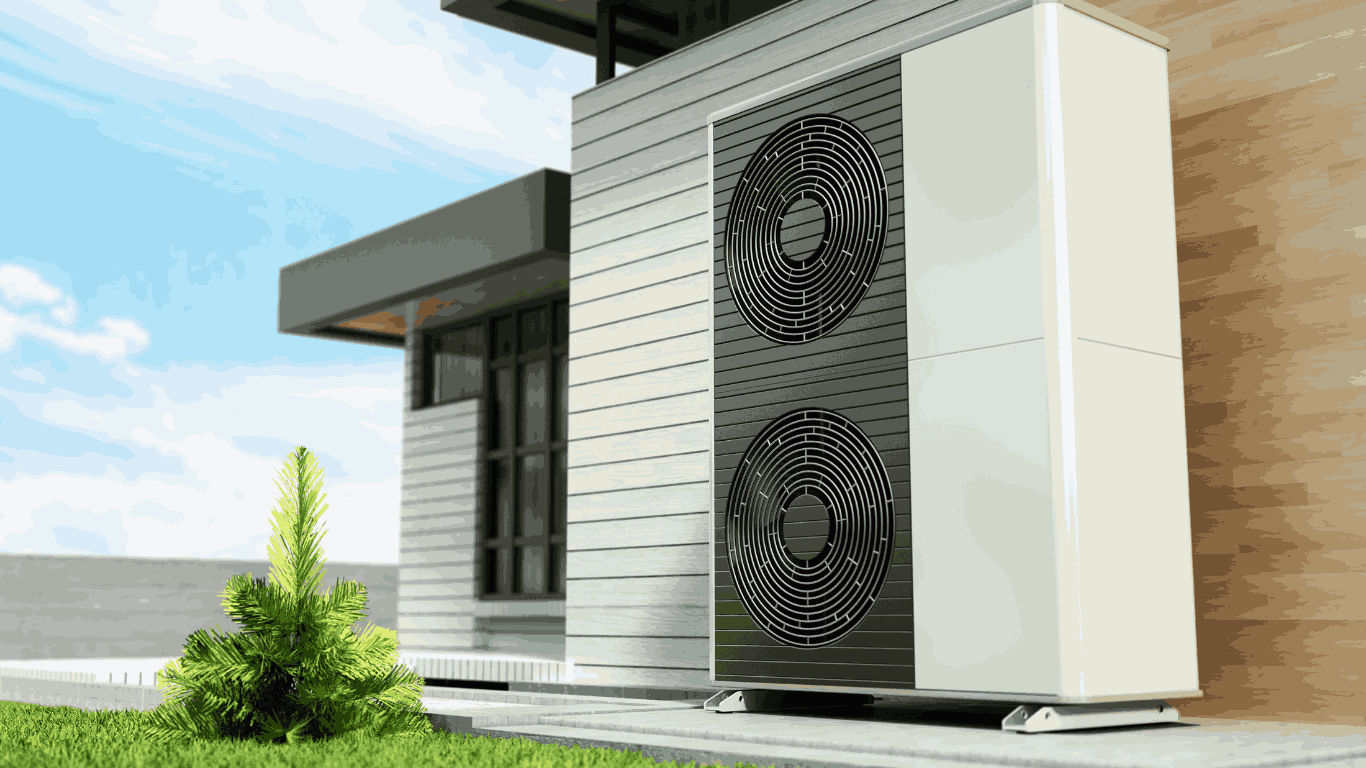

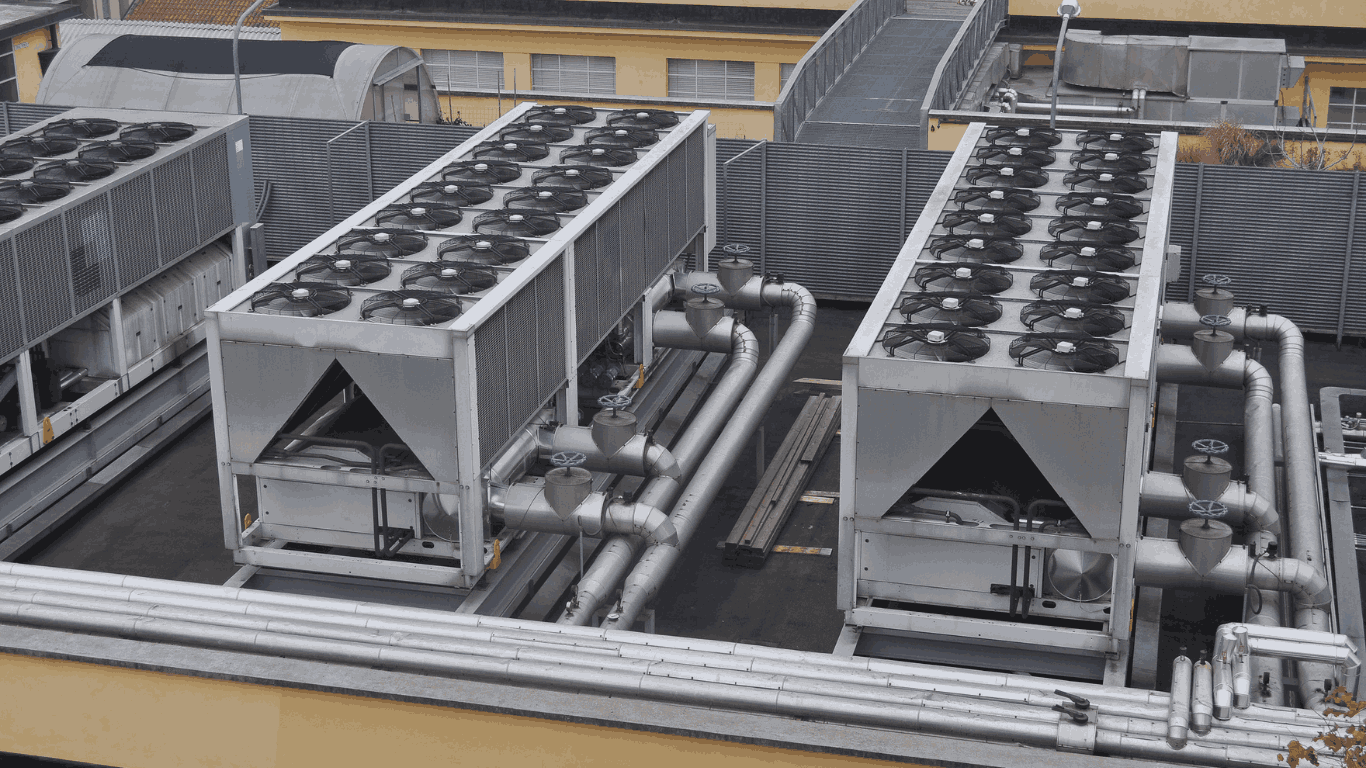

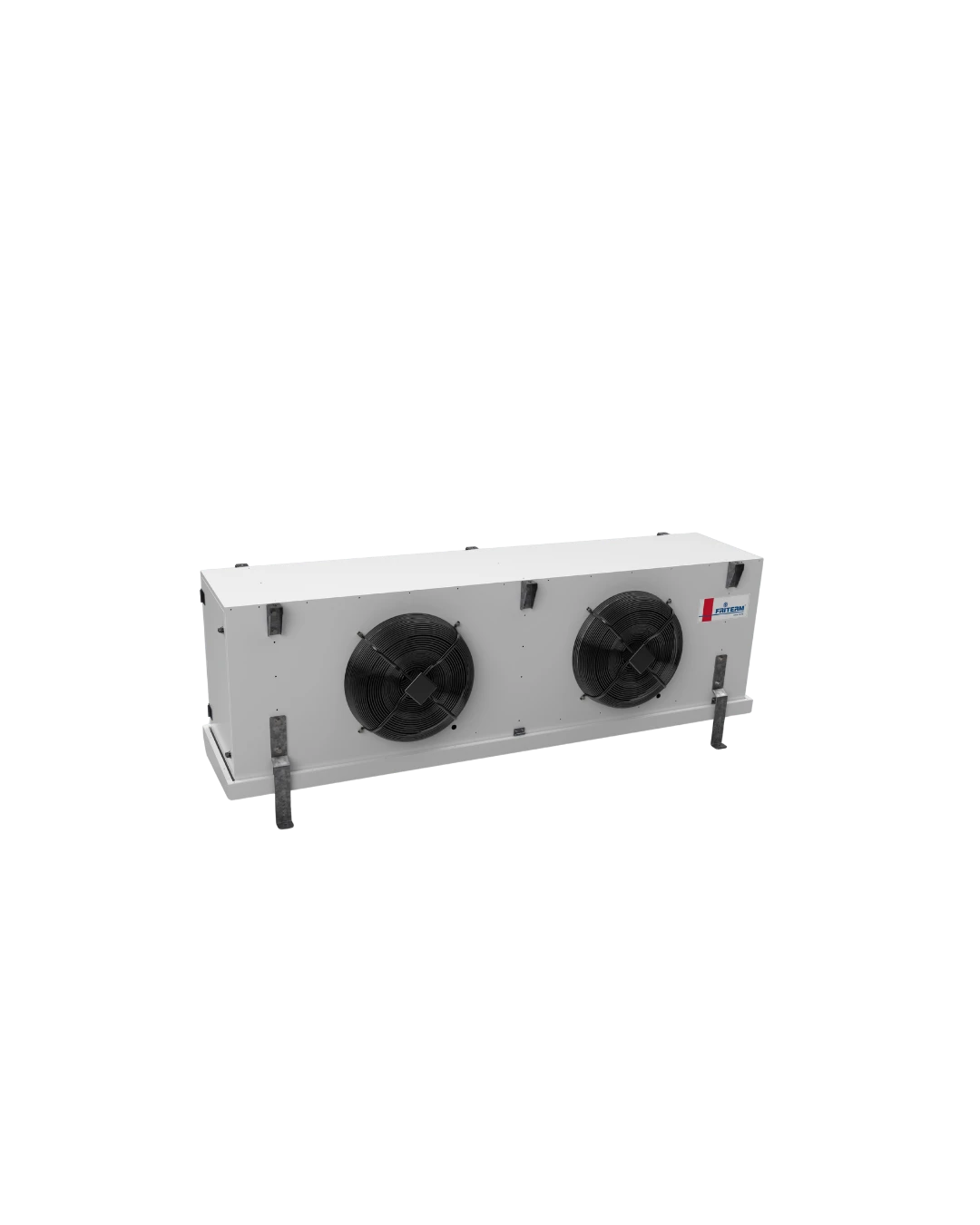

We have accumulated experience and knowledge in project design, manufacturing, contracting and sales within the commercial and industrial refrigeration and air conditioning sector. Over time, we have narrowed our range of activities to focus on the production of air-cooled condensers, cold room evaporators, dry coolers, wet/steam air heaters and coolers, oil coolers, and heat recovery coils, specializing in finned tube heat exchangers.

FRİTERM A.Ş. has two production facilities with a total closed area of 51,000 m² in Tuzla-İstanbul and the Dilovası Makina İhtisas OSB, employing more than 350 competent personnel and utilizing modern machinery and equipment.

FRİTERM A.Ş. shares the pride of maintaining its leadership in its field with all its customers by certifying its ISO 9001:2015 Quality Assurance System with TÜV-NORD.

FRTCOILS V6, the heat exchanger design software developed by FRİTERM, has successfully completed performance tests for wet air heating and cooling coils and has been awarded a Eurovent Coil (COIL) certificate. In addition, the following products are Eurovent certified under the program: dry coolers, air-cooled condensers, direct expansion (DX) air coolers, CO₂ gas coolers, and heat exchanger coils. High-efficiency heat recovery coils are Eurovent certified under the HRSCOIL program.

All FRİTERM products are manufactured in accordance with the relevant European New Approach Directive. CE marking of the products is carried out in accordance with current European Union Directives. Furthermore, the EAC certification process, which is mandatory for exports to the Russian Federation and CIS (Commonwealth of Independent States) countries, has been completed for all Friterm products.

FRİTERM A.Ş. is committed to absolute customer satisfaction and sets itself apart by prioritizing research and development and original design.

FRİTERM A.Ş.'s quality policy is “To be one of the world's leading teams that is sensitive to society and the environment, meets the highest levels of customer satisfaction, provides quality and economical products and services on time, is innovative and continuously improves its systems”.

We have two production facilities, with a total enclosed area of 51,000 m².

Tuzla production facility has a closed area of 13,000 m².

Dilovası production facility has a closed area of 38,000 m².

ISO 9001:2015

ISO 9001:2015

We are proud to share with all our customers the fact that we have certified our ISO 9001:2015 Quality Assurance System with TÜV-NORD, thereby maintaining our leadership in our field of activity.

350 competent personnel

FRTCOILS is coil design software developed by Friterm. It is EUROVENT certified, and performance approved for wet-air heating and cooling coils, as well as dry coolers.

Friterm is committed to achieving absolute customer satisfaction and sets itself apart through its focus on research and development, and original design in its products and services.

At FRİTERM A.Ş., we are committed to achieving absolute customer satisfaction. We differentiate our products by prioritizing research and development and original design.

Our quality policy is to be one of the world's leading teams, sensitive to society and the environment, providing quality, economical products and services on time, and continuously improving our systems.

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)