R&D studies are carried out multifariously to achieve designs that are highly performant, low-cost and have a minimal environmental impact.

In this context, we follow and incorporate the latest scientific and technical developments into our R&D infrastructure through domestic and international collaborations and consultancy services, particularly with regard to software and design studies.

The studies carried out at the FRITERM R&D department

can be summarized under three main headings:

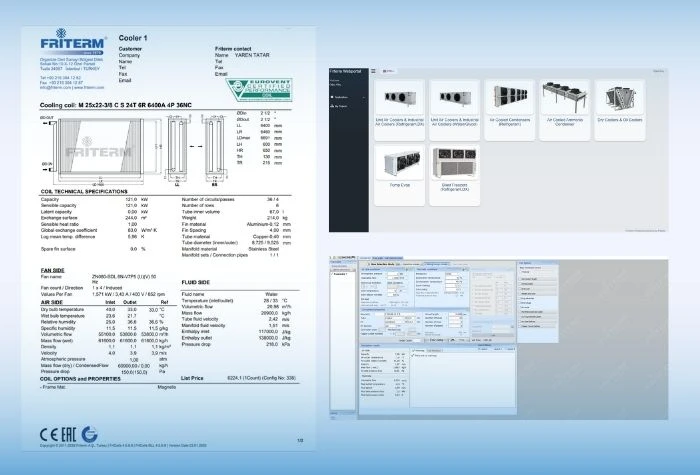

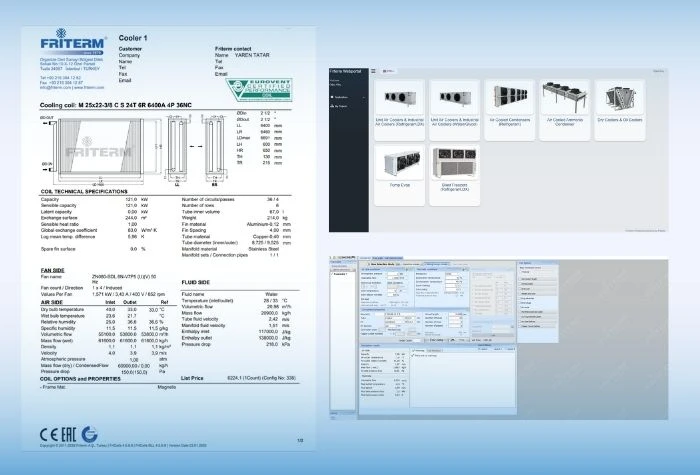

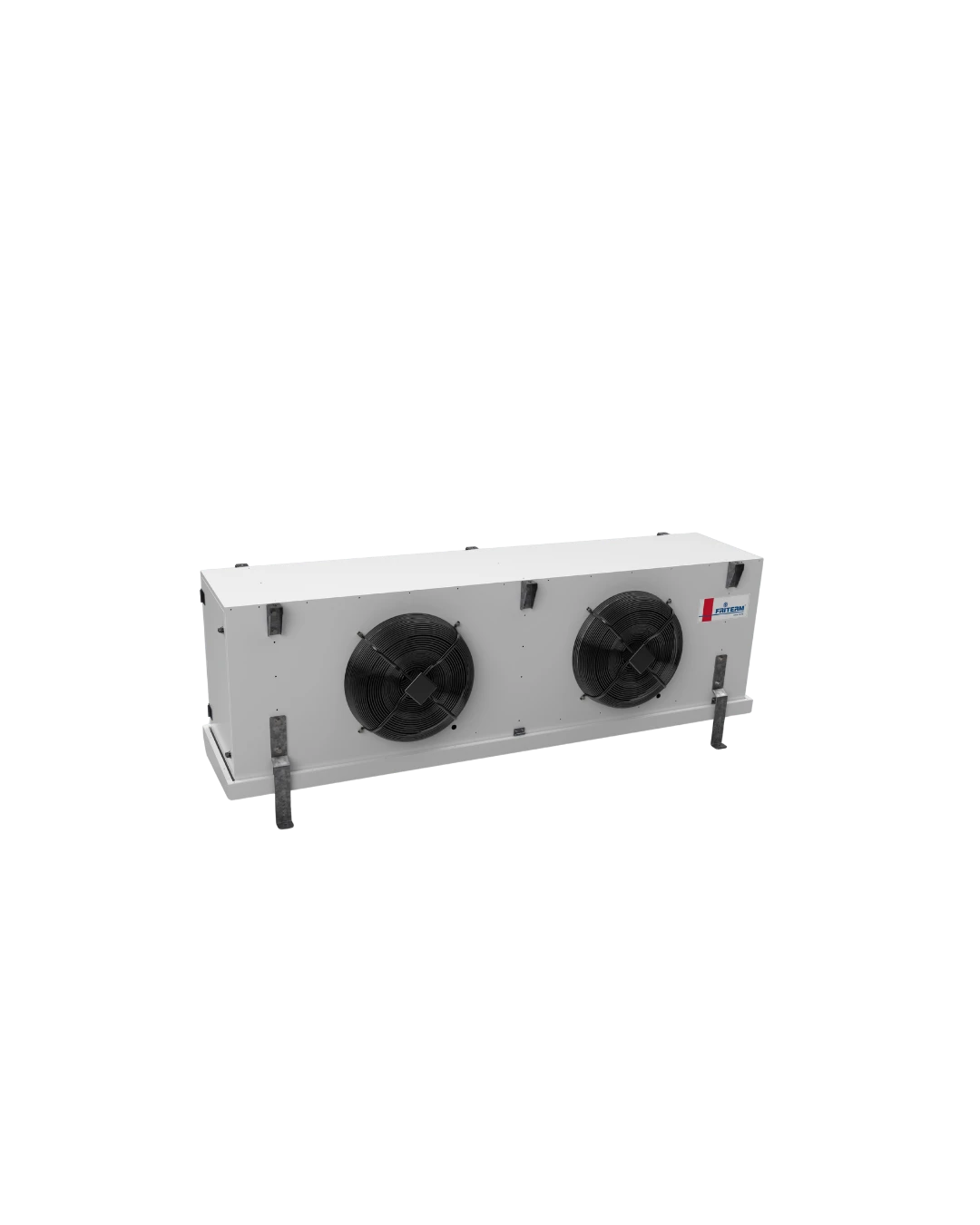

Friterm Thermal Devices Inc. The Ur-GE department operates in the fields of thermal design, development and optimization of poultry heat exchanges. The main objective of the unit is to create design solutions that maximize the energy efficiency and performance of the products. In this process, the products are optimized not only for theoretical calculations, but also to provide high efficiency and reliability in field applications. Each design developed is evaluated with a systematic engineering approach and it is aimed to provide fast and effective solutions to the changing needs of the market.

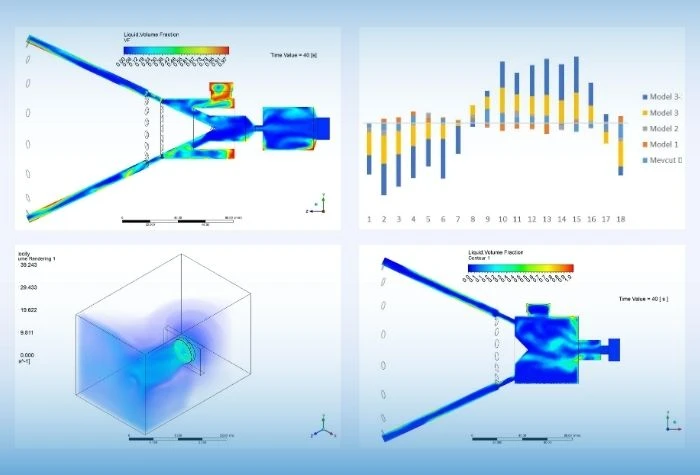

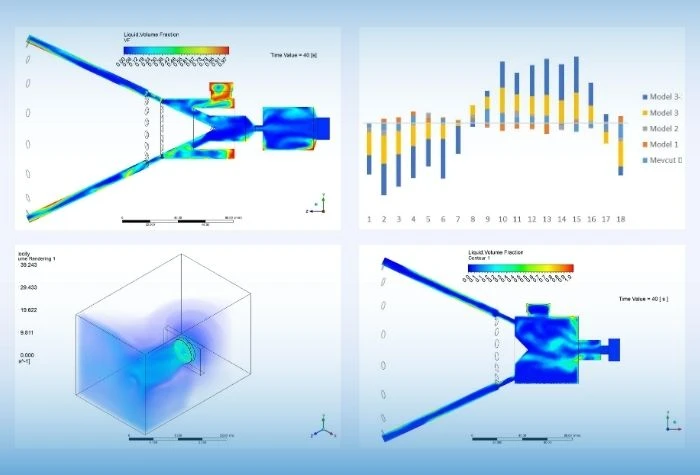

Product development studies, digital fluid dynamics (CFD) analyzes, numerical modeling techniques and parametric optimization methods are actively used. In the design process, the thermal and flow performances of the products are analyzed in a comprehensive manner considering different working conditions, fluid characteristics and geometric variations. In addition to ISO and Asme standards in all development processes, CE certification requirements are also compliance. With its engineering approach based on scientific principles, Friterm aims to bring high -efficiency, safe and heat exchanger solutions to the sector in accordance with international standards.

Thanks to the computational infrastructure developed as a result of software studies, the thermal design and dimensioning of products can be realized. This is followed by the completion of constructive design and finalization of the product through prototype production.

In addition to the structural verification of newly designed products, performance verification is carried out under laboratory conditions in accordance with the EN 328 standard.

Friterm Thermal Devices Inc. The R & D Laboratory was structured to experimentally confirm the thermal performance of poultry heat exchanges and to validate the theoretical design calculations. The laboratory includes comprehensive test infrastructures such as two test rooms, oil cooler test unit and indoor/outdoor wind tunnel established in different years. All test activities are carried out in accordance with TS EN 328, EN 327, EN 1216, EN 1048 and Ashrae 33 standards and provide scientific and reliable data support to laboratory product development processes.

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)

-webp.webp)